Ọnụ ahịa kacha nta:100 Kilogram

Nkọwa ngwugwu:

Mkpọ A: 16kg / igwe gbọmgbọm

Mkpọ B: 24KG Plastic Barrel

Mkpọ C: dabere na ọnụọgụ nke onye nnọchi anya B A

Oge Mbuga ozi:Ụbọchị iri mgbe nnata nke ugwo mbu

Ikike inye:2 ton kwa ụbọchị

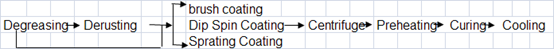

Usoro mkpuchi:Tinye Spin & fesa

Agba:Ọlaọcha

PH:3.8-5.2

Nnukwu ike ndọda:1.33 ± 0.05 (Ịgbasa) 1.33 ± 0.05 (Mkpuchi Mkpuchi)

Viscosity:Dị ka ọrụ chọrọ.

Okpomọkụ na-arụ ọrụ:20 ± 2 ℃

Nkọwa

JH-9382 nwere ngwugwu atọ: A,B na C;

ngwugwu A: Ọ bụ ọlaọcha isi awọ slurry nke ejiri kemịkalụ jikọtara ya na ọmarịcha flake Zn, ọmarịcha flake Al na mgbakwunye organic.

Mkpọ B: Ọ bụ mmiri ngwọta nke tumadi jikọtara ya na corrosion protecion mgbakwunye, akpan akpan regulator mmiri ngwọta wdg.

Mkpọ C: Ọ bụ tackifier nke mkpuchi nke tumadi mejupụtara cellulose ọcha ma ọ bụ odo ntụ ntụ.

Njirimara arụmọrụ:

Ihe nkiri ahụ bụ ọlaọcha na-acha ọcha, mma elu elu, elu corrosion eguzogide, mma mkpuchi.

Usoro mkpuchi

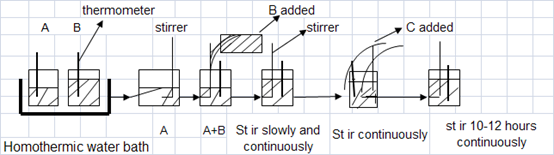

1. Mix Ratio

Mkpọ A: 16.0kg

Mkpọ B: 24.0 n'arọ (ọnụ ọgụgụ nwere ike ịba ụba nke ọma ma ọ bụrụ na mkpuchi ịgba)

Mkpọ C: 0-50 g (dị ka ọchịchọ viscosity dị iche iche)

2. Tupu ngwakọta, Nọgidenụ arọ A & B n'ime mmiri saa na 25 ± 2 ℃, mgbe ahụ, kpalie A na-eme ka metal slurry agbasa uniformly site ugboro igwekota, mgbe A na-n'ụzọ zuru ezu evenly chụsasịrị, belata agitating ọsọ na 60r / min, na tinye B .

Tinye B na mkpali A nwayọọ nwayọọ.N'oge a, gbọmgbọm okpomọkụ ga-arị elu, mgbe ọ ruru 35 ℃, mmalite refrigerating ngwaọrụ ka gbọmgbọm okpomọkụ na-adịgide adịgide na 35 ℃.

3.Tinye B na edemede A nwayọọ nwayọọ.N'oge ahụ, gbọmgbọm okpomọkụ ga-arị elu, mgbe ọ esịmde 35 ℃, mmalite refrigerating ngwaọrụ na gbọmgbọm okpomọkụ mgbe niile na 35 ℃.

4. Nwuo ngwakọta banyere 1 ~ 2 awa ngwa ngwa mgbe B agbakwunyere, wee tinye C. C kwesịrị powdered ma ọ bụrụ na akpụ adị. 12 awa na-aga n'ihu.

5. A ga-enyocha mkpuchi ahụ site na 100 mesh igwe anaghị agba nchara tupu awụsa n'ime gbọmgbọm dip.

6. Ngwa njikwa okpomọkụ kwesịrị ịkwado ya na gbọmgbọm dip iji mee ka okpomọkụ nke mkpuchi na 22 ± 2 ℃.

(Ọ bụrụ na ọnọdụ okpomọkụ dị elu, agba ahụ nwere ike ịka njọ, na viscosity ga-arụ ọrụ.) Ekwesịrị ịkwanye mkpuchi ahụ gburugburu gburugburu ka ọ na-agbasasịkwa ya.

7. Nyochaa njupụta, PH, okpomọkụ, viscosity na Cr6 + ọdịnaya nke mkpuchi kwa awa 8 ma ọ bụrụ na-arụ ọrụ na-aga n'ihu.

Ngwakọta eserese

Nlebara anya

Chemicals ndị ọzọ dị ka ụdị acid ọ bụla, nnu alkali enweghị ike ịgwakọta ya na mkpuchi, n'ihi na ihe ndị a nwere ike mee ka Zn & Al plate mee ka mkpuchi ahụ mebie.

Zere irradiation nke anwụ na ultraviolet ray ruo ogologo oge mgbe ị na-arụ ọrụ, ma ọ bụghị na ọ ga-eme ngwa ngwa ịka nká ma ọ bụ polymerization nke mkpuchi .

Ọ dị ezigbo mkpa ịchịkwa okpomọkụ nke mkpuchi.Ọ bụrụ na ọnọdụ okpomọkụ nke mkpuchi na-agbanwe mgbe ọ na-arụ ọrụ, ọ ga-emetụta viscosity, mgbe ahụ, effec mkpuchi qutity na workpiece.Ya mere, mmekọrịta dị n'etiti okpomọkụ, viscosity na spinning usoro kwesịrị ịchịkwa nke ọma mgbe mkpuchi.

Viscosity ga-adị iche ma ọ bụrụ na usoro mkpuchi dị iche.Họrọ obere data ma ọ bụrụ mkpuchi ịgba, wee họrọ oke data ma ọ bụrụ na itinye mkpuchi mkpuchi.

Data teknụzụ

| Mba. | Ihe | Data |

| 1 | Agba | Ọlaọcha |

| 2 | Usoro mkpuchi | Dip Spin & Spraying |

| 3 | PH | 3.8-5.2 |

| 4 | Cr6+ | ≥25g/L |

| 5 | Nnukwu ike ndọda | 1.33 ± 0.05 (ịgba mmiri) 1.33 ± 0.05 (nkpuchi mgbụsị akwụkwọ) |

| 6 | Viscosity | Dị ka ọrụ chọrọ. |

| 7 | Ọnọdụ okpomọkụ na-arụ ọrụ | 20 ± 2 ℃ |