Ọnụ ahịa kacha nta:100 Kilomita

Nkọwa ngwugwu:

Mkpọ A: 20kg / igwe gbọmgbọm

Mkpọ B: 20KG Plastic Barrel

Mkpọ C: dabere na ọnụọgụ nke onye nnọchi anya B A

Oge Mbuga ozi:Ụbọchị iri mgbe nnata nke ugwo mbu

Usoro ịkwụ ụgwọ:L/C, T/T

Ikike inye:2 ton/ton kwa ụbọchị

Agba:Ọlaọcha

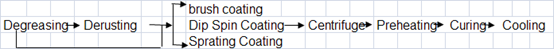

Usoro mkpuchi:Tinye ma fesa mkpuchi

PH (20 ℃):5.0-8.0

Nnukwu ike ndọda:1.30-1.40 (Mkpuchi ịgbasa)

Viscosity:Dị ka ọrụ chọrọ

Okpomọkụ na-arụ ọrụ:22± 2 ℃

Nkọwa

JH-9610 bụ ngwugwu atọ mejupụtara: A,B na C;

ngwugwu A: Ọ bụ ọlaọcha isi awọ slurry nke ejiri kemịkalụ jikọtara ya na ọmarịcha flake Zn, ọmarịcha flake Al na mgbakwunye organic.

Mkpọ B: Ọ bụ mmiri ngwọta nke tumadi jikọtara ya na corrosion protecion mgbakwunye, akpan akpan regulator mmiri ngwọta wdg.

Mkpọ C: Ọ bụ tackifier nke mkpuchi nke tumadi mejupụtara cellulose ọcha ma ọ bụ odo ntụ ntụ.

Njirimara arụmọrụ:

1. Chrome efu;

2. Ezi n'elu imecha arụmọrụ, elu mgbochi corrosion, ala esemokwu ọnụọgụ;

3. Ọ dịghị hydrogen brittleness, ọ dịghị pickling usoro;

4. Ezigbo nguzogide okpomọkụ;

5. Ezi SST awa, mgbochi ịka nká okirikiri ogologo, nwere ike uwe ọzọ ngwaahịa n'okpuru otu usoro ọnọdụ.

Usoro mkpuchi

1. Mix Ratio

Mkpọ A: ngwugwu B: ngwugwu C = 1: 1: X (dị ka ọchịchọ viscosity dị iche iche si dị)

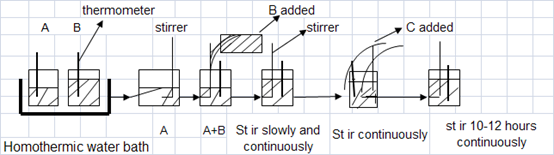

2. Tupu ngwakọta, Nọgidenụ arọ A & B n'ime mmiri saa na 25 ± 2 ℃, mgbe ahụ, kpalie A na-eme ka metal slurry agbasa uniformly site ugboro igwekota, mgbe A na-n'ụzọ zuru ezu evenly chụsasịrị, belata agitating ọsọ na 60r / min, na tinye B .

3. Tinye B na mkpali A nwayọọ nwayọọ.

4. Nwuo ngwakọta banyere 1 ~ 2 awa mgbe B gbakwunyere, wee tinye C. C kwesịrị powdered ma ọ bụrụ na akpụ adị. ~ 12 awa obere na na-aga n'ihu.

Ngwakọta eserese

Nlebara anya

1. Chemicals ndị ọzọ dị ka ụdị acid ọ bụla, nnu alkali enweghị ike ịgwakọta ya n'ime mkpuchi, n'ihi na ndị a nwere ike ime ka Zn & Al plate mee ka mkpuchi ahụ mee agadi.

2. Zere irradiation nke anwụ na ultraviolet ray ruo ogologo oge mgbe ị na-arụ ọrụ, ma ọ bụghị na ọ ga-eme ka ịka nká ma ọ bụ polymerization nke mkpuchi.

3. Ọ dị ezigbo mkpa ịchịkwa okpomọkụ nke mkpuchi.Ọ bụrụ na ọnọdụ okpomọkụ nke mkpuchi na-agbanwe mgbe ọ na-arụ ọrụ, ọ ga-emetụta viscosity, mgbe ahụ, effec mkpuchi qutity na workpiece.Ya mere, mmekọrịta dị n'etiti okpomọkụ, viscosity na spinning usoro kwesịrị ịchịkwa nke ọma mgbe mkpuchi.

4. Viscosity ga-adị iche ma ọ bụrụ na usoro mkpuchi dị iche.Họrọ obere data ma ọ bụrụ mkpuchi ịgba, wee họrọ oke data ma ọ bụrụ na itinye mkpuchi mkpuchi.

Data teknụzụ

| Mba. | Ihe | Data |

| 1 | Agba | Ọlaọcha |

| 2 | Usoro mkpuchi | Nri & Ịfesa |

| 3 | PH | 4.8-7.5 |

| 4 | Nnukwu ike ndọda | 1.45± 0.1 (mkpuchi ịgbasa) |

| 5 | Viscosity | 25 ~ 40s (mkpuchi ịgbasa) |