Nrụrụ aka bụ mmebi ma ọ bụ mmebi nke ihe ma ọ bụ ihe onwunwe ha kpatara site na omume nke gburugburu ebe obibi.Ọtụtụ nrụrụ na-apụta na gburugburu ikuku, nke nwere ihe ndị na-emebi emebi na ihe ndị na-emebi emebi dị ka oxygen, iru mmiri, mgbanwe okpomọkụ na mmetọ.

Nhịhịa ịgba nnu bụ ụdị corrosion ikuku na-ahụkarị na nke na-emebi emebi.Ihe na-akpata nrụrụ nnu n'elu ihe igwe sitere na ion chloride dị na elu igwe na-abanye na oyi akwa oxidation na oyi akwa nchebe yana mmeghachi omume metal electrochemical nke ime.N'otu oge ahụ, ion ion chloride nwere ụfọdụ ike hydration, nke dị mfe na-adsorbed na metal elu pores na cracks na iji dochie oxygen na oxide oyi akwa, si otú ịgbanwe insoluble oxide n'ime soluble chloride na passivated. steeti elu n'ime elu nọ n'ọrụ.

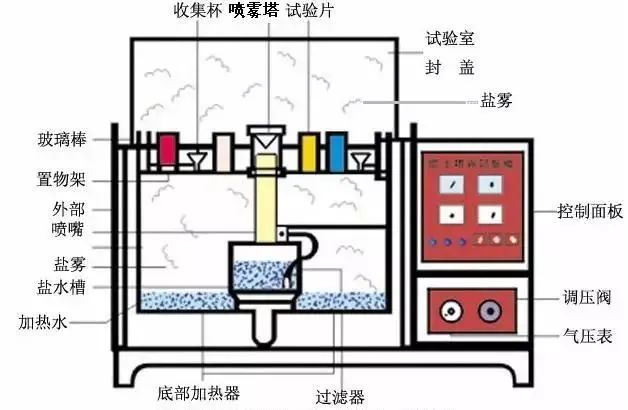

Nnuịgbasa nchebe corrosionule bụ ule gburugburu ebe obibi nke na-ejikarị ọnọdụ ịgba gburugburu nnu simulated emepụtara site na ngwa nnwale ịgba nnu mebere iji chọpụta nguzogide nrụrụ nke ngwaahịa ma ọ bụ ihe igwe.A na-ekewa ya n'ụdị ule abụọ: nnwale mkpughe gburugburu ebe obibi, na nnwale ịgbasa nnu n'ike n'ike.

N'ime nyocha gburugburu ebe obibi nnu simulation, a na-eji ụlọ nyocha nnu nnu nwere ụfọdụ oke ohere, a na-emepụta gburugburu ebe ịgba nnu site n'iji ụzọ arụrụ arụ na oke oghere ya, iji chọpụta arụmọrụ na ogo corrosion nnu nnu. iguzogide ngwaahịa.

Ntụnye nnu nke chloride na gburugburu ebe a na-agba nnu nwere ike ịbụ ọtụtụ oge ma ọ bụ ọtụtụ ugboro ihe nrịba nnu na gburugburu ebe obibi nkịtị, si otú a na-abawanye ọnụ ọgụgụ corrosion nke ukwuu ma na-ebelata oge iji nweta nsonaazụ ya.Dịka ọmụmaatụ, ọ nwere ike were otu afọ iji mebie mgbe ị na-anwale ihe nlele ngwaahịa na gburugburu ikuku, ebe ị nwere ike nweta nsonaazụ ule yiri nke ahụ ozugbo awa 24 gachara na gburugburu ịme anwansị simulation nnu.

Enwere ike kewaa ịgba nnu simulated ụlọ nyocha ụzọ anọ.

(1) Nnwale ịgba nnu nnu na-anọpụ iche (NSS ule) bụ usoro nnwale corrosion kacha eme ihe na nke izizi.Ọ na-eji 5% sodium chloride nnu mmiri ngwọta, na pH uru na-agbanwe ka a na-anọpụ iche iche (6.5 ~ 7.2) dị ka ihe ngwọta ịgba.Nnwale ule bụ 35 ℃, na achọrọ sedimentation ọnụego nke nnu ịgba bụ 1 ~ 2ml / 80cm / h.

(2) A na-emepụta ule ịgba mmiri acetic acid (Nnwale ASS) na ndabere nke nnwale ịgba nnu na-anọpụ iche.Ọ bụ na 5% sodium chloride ngwọta na ụfọdụ glacial acetic acid, nke mere na ngwọta PH uru na-ebelata ihe dị ka 3, ngwọta na-aghọ acidic, na nnu ịgba kpụrụ emesị ghọọ acidic si na-anọpụ iche nnu ịgba.Ọnụego corrosion ya dị ihe dị ka ugboro atọ ngwa ngwa karịa ule NSS.

(3) Nnwale ịgbasa nnu ọla kọpa accelerated acetate (CASS test) bụ nnwale nrụrụ nnu ngwa ngwa nke mba ofesi mepere emepe.Okpomọkụ nnwale bụ 50 ℃.A na-agbakwunye obere chloride nnu ọla kọpa na ngwọta nnu iji kpalite corrosion siri ike.Ọnụego corrosion ya dị ihe dị ka okpukpu asatọ karịa nke ule NSS.

(4) Nnwale ịgba nnu ọzọ bụ nnwale ịgba nnu zuru oke, nke bụ n'ezie nnwale ịgba nnu na-anọpụ iche gbakwunyere iru mmiri na ule okpomọkụ.A na-ejikarị ya maka ngwaahịa ụdị oghere.Site na ntinye nke gburugburu ebe obibi tidal, a na-emepụta corrosion nnu nnu ọ bụghị naanị n'elu kamakwa n'ime ngwaahịa ahụ.A na-atụgharị ngwaahịa a ọzọ n'etiti ncha nnu na iru mmiri na gburugburu okpomọkụ, mgbe ahụ, a ga-enyocha ihe eletriki na ígwè ọrụ nke ngwaahịa ahụ maka mgbanwe ọ bụla.

Mkpebi nsonaazụ

A na-enye nsonaazụ nnwale nke nnwale nnu nnu n'ụdị qualitative karịa ụdị ọnụọgụ.Enwere ụzọ anọ akọwapụtara nke ọma.

(1) Usoro mkpebi ọkwa.

Na usoro a, kewaa oke nke mpaghara corrosion na mpaghara mkpokọta n'ime ọkwa dị iche iche, ma chọpụta ọkwa ụfọdụ dị ka ntọala ruru eru maka mkpebi siri ike.Usoro a dabara adaba maka nyocha nke ihe atụ dị larịị.

(2) Usoro mkpebi nke ịtụ.

Site n'ịtụle ịdị arọ nke sample tupu na mgbe ule corrosion gachara, gbakọọ arọ furu efu n'ihi corrosion, ma kpee ikpe.ịgbasa nchedo corrosionàgwà nke sample.Usoro a dabara adaba karịsịa maka ntule nke ụfọdụ nguzogide corrosion metal.

(3) Usoro nyocha ọnụọgụ data corrosion.

Usoro a na-enye ọkwa ntụkwasị obi nke imepụta ule corrosion, nyocha data corrosion, na ikpebi data corrosion, nke a na-ejikarị maka nyocha na ọnụ ọgụgụ corrosion, karịa maka ikpebi ogo ngwaahịa.

Nnwale ịgba nnu nke igwe anaghị agba nchara

Ebe ọ bụ na e mepụtara ya na mmalite narị afọ nke iri abụọ, ndị na-eji ihe na-emepụta ihe na-eguzogide ọgwụ na-akwado ya nke ukwuu n'ihi uru ya gụnyere oge na ọnụ ahịa dị ntakịrị, nwee ike ịnwale ụdị dị iche iche, na-enye nsonaazụ dị mfe ma doo anya.

Na omume, nnwale ịgba mmiri nke igwe anaghị agba nchara bụ nke a kacha mara amara, ndị na-ahụ maka ya ga-amarịrị awa ole nlere nnu nwere ike ịdịru maka ihe a.

Ndị na-ere ihe ga-agbatị oge nlele nchara nke igwe anaghị agba nchara na usoro dị ka passivation ma ọ bụ ịbawanye ọkwa elu elu.Otú ọ dị, ihe kachasị mkpa na-achọpụta bụ ihe mejupụtara igwe anaghị agba nchara n'onwe ya, ya bụ ọdịnaya nke chromium, molybdenum na nickel.

Ka ọdịnaya nke ma chromium na molybdenum dị elu, ka nguzogide corrosion na-achọ maka pitting na crevice corrosion malite ịpụta.A na-egosipụta nguzogide corrosion a site na uru nke a na-akpọ pitting resistance (PRE): PRE =%Cr + 3.3 x%Mo.

Ọ bụ ezie na nickel adịghị amụba nguzogide ígwè na pitting na crevice corrosion, ọ nwere ike ịdị irè n'ibelata ọnụ ọgụgụ corrosion ahụ ozugbo usoro mmebi ahụ malitere.Ya mere, igwe anaghị agba nchara austenitic nwere nickel na-eme nke ọma na nyocha ịgba nnu na nchara na-erughị obere nchara nickel ferritic igwe anaghị agba nchara nwere ihe ndị yiri ya.

Ekwesiri ighota na nnuịgbasa nchebe corrosionule nwere nnukwu ihe ndọghachi azụ mgbe a na-anwale arụmọrụ igwe anaghị agba nchara.Ọdịnaya chloride nke nnu n'ule nfe nnu dị oke oke ma karịa nke ezigbo gburugburu ebe obibi, yabụ igwe anaghị agba nchara nke nwere ike iguzogide corrosion na ngwa n'ezie nwere ọdịnaya chloride dị obere ga-emebikwa na nnwale ịgba nnu.

Nnwale ịgba nnu na-agbanwe omume corrosion nke igwe anaghị agba nchara, nke enwere ike iwere na ọ bụghị nnwale agbagoro ngwa ngwa ma ọ bụ nnwale simulation.Nsonaazụ bụ otu akụkụ na enweghị njikọ kwekọrọ na arụmọrụ nke igwe anaghị agba nchara nke emechara tinye n'ọrụ.

Yabụ ị nwere ike iji nnwale ịgba nnu iji tụnyere nguzogide corrosion nke ụdị igwe anaghị agba nchara dị iche iche, mana nnwale a nwere ike ịkọ ihe.Mgbe ị na-ahọrọ otu ihe igwe anaghị agba nchara, nnwale ịgba nnu naanị anaghị enye ozi zuru oke n'ihi na njikọ dị n'etiti ọnọdụ ule na ebe ngwa ngwa anaghị adịkarị.

Tụkwasị na nke ahụ, ụdị ígwè dị iche iche enweghị ike iji ya tụnyere ibe ha, n'ihi na ihe abụọ a na-eji na ule ahụ nwere usoro corrosion dị iche iche, ya mere nsonaazụ ule na mkpa nke njedebe ikpeazụ nke gburugburu ebe obibi abụghị otu.

Oge nzipu: Jul-08-2022